Working principle

With semiconductor laser image patterns are directly related to the exposure to the net on the billet coated with emulsion,laser light,after the completion of development into the water,high temperature,can be put into production. Enhancement curing the finished product Image color separation Blu-ray billet making machine image exposure to the net

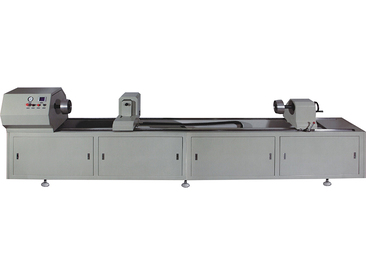

Technical parameters

|

Product model |

XC3500 |

|

Equipment size |

5100×780×1300(mm) |

|

Biggest pattern size |

3400(mm) |

|

Rotary screen size |

640 /819 /914 /1016 (Cpational) |

|

Laser |

16 /24 (Cpational) |

|

System network speed |

8min/㎡ |

|

Making precision |

720dpi |

|

Power supply |

AC380V 2KW 50-60HZ |

|

Temperature |

Temperature20-25℃ |

Product advantage

● Japan imported laser,light source to provide stable and reliable work.

● High performance and high precision optical focusing system,improving the system of network precision.

● Using multiple independent sources(standard for 16 road)design,greatly improve the speed,exposure 2 meters long and 640 mm specifications of the cylinder can complete 12 minutes.

● The TEC temperature control system based on digital temperature sensor, adopt the whole bridge(H bridge) efficient synchronous rectifier control.

● Low pattern digital output direct exposure,can accurately reflect the manuscript,eliminates the film exposure of network loss and packages were pick up version of the problem.

● The production cost is low

Use direct exposure, save the cost of film ,ink or wax,true no consumables system network.

● Easy to operate

Humanized control flat, simple software to print control interface,the operation staff be clear at a glance, simple operation process,but also saves the previous film bag piece of many complicated operation.

|

Confidence comes from strength, strength comes from constant efforts!